Xi’s reply letter inspires momentum in strong ‘Chinese hearts’ creation for domestic aircrafts

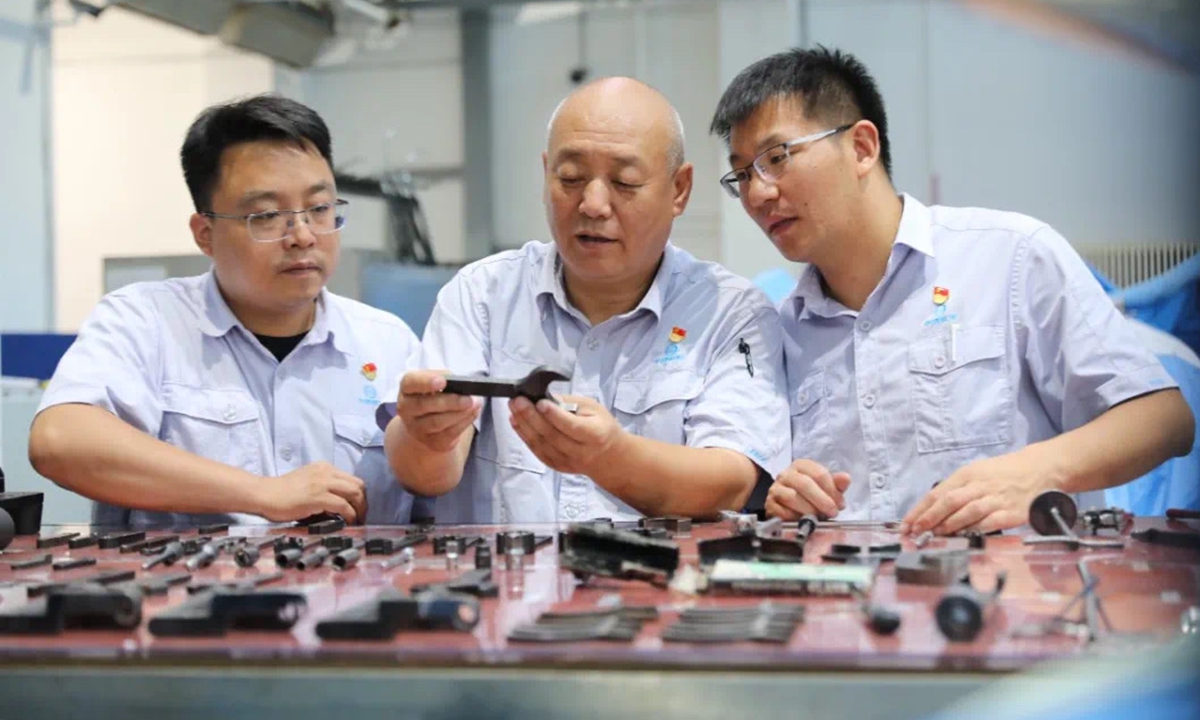

Li Zhiqiang (center) and his colleagues examine tools in a workshop. Photo: Courtesy of the Aero Engine Corporation of China

Editor's Note:

Chinese people believe that letters are as valuable as gold. For thousands of years, letters, across mountains and oceans, have been delivering writers' sentiments and conveyed friendship and expectations.

Xi Jinping, general secretary of the Communist Party of China (CPC) Central Committee and Chinese president, has managed to find time to reply to some letters from different parts of society and the world despite his busy work schedule.

Through his letters, Xi has corresponded with international friends from all walks of life on numerous occasions, part of a series of excellent stories of China's international exchanges in the new era. The letters have also added vivid color to the diplomacy between China and other countries.

The Global Times traced and contacted some of the recipients of Xi's letters, to hear the inspiring stories behind the letters and their communication with the president.

In this installment, Global Times reporters spoke with technicians from the Aero Engine Corporation of China (AECC) Shenyang Liming Aero-Engine Co, Ltd to learn about their stories of devoting themselves to the research and development of China's domestic aero engines and how Xi encouraged them to inherit and carry forward the spirit of a great country's craftspeople, along with a thorough review of how China gradually created its own aero engines.

"A workman must first sharpen his tools if he wants to do his work well," is a Chinese saying that emphasizes not only the importance of tools of a craft, but indicates the vital role of the craftsman who creates the tools.

"Your work is important and honorable," Chinese President Xi Jinping, who is also general secretary of the Communist Party of China (CPC) Central Committee and chairman of the Central Military Commission, told technicians at the Li Zhiqiang Class in Aero Engine Corporation of China (AECC) Shenyang Liming Aero-Engine Co Ltd, while Xi visited the corporation in 2013 to review its work in developing and producing aero engines.

A decade later, in a letter to the class on September 1, Xi spoke highly of the contribution of technicians in the research and development process of China's aero engines.

Xi emphasized that aero engines are a vital national asset and an important reflection of the country's scientific and technological strength and innovation capabilities. "I hope you will remember your mission and responsibilities, firmly uphold the aspiration of serving the aviation industry, promote the spirit of model workers and craftsmen, strive to make more technological breakthroughs, accelerate the pace of independent research and development of aviation engines, and enable Chinese aircraft to have a stronger 'Chinese heart,'" Xi said in the letter.

Until recently, aero engines had been a shortcoming in China's aircraft development, but that impression changed drastically when the Chinese People's Liberation Army (PLA) Air Force's most advanced stealth fighter jet, the J-20, made its first public appearance equipped with a pair of domestically developed engines in 2021, replacing imported engines used in the past.

Aero jeweler

The aero engine is deemed the "crown jewel" of modern industry. An aero engine is composed of tens of thousands of components of different shapes and materials. The circuit of the engine is like blood vessels around the human body, which requires a very high degree of precision to assemble and allows no room for error.

Technicians from the Li Zhiqiang Class, named after national model worker and national technical expert Li Zhiqiang, are exactly the people who are responsible for assembling aero engines and gas turbines.

"At that time, the president said our work 'is important and honorable.' He also said that the turbine vanes and blades are as valuable as diamonds. We always recall such acknowledgement and encouragement and use them as fuel to keep striving forward," said Li Zhiqiang, recalling Xi's visit a decade ago.

In a letter to Xi, Li and seven other technicians reported achievements made in strengthening technological innovation and promoting independent research and development in the aero industry over the last decade, expressing their determination to accelerate the pace of independent research and development of aero engines and build a strong aviation nation.

As the initiator among a total of eight technicians from the class who wrote the letter, Li told the Global Times that Xi's reply letter showed "extreme recognition, was encouraging, and inspirational" to the team. He shared the letter's contents to all 62 members of the team. "We must keep in mind his care, trust, and ardent expectations, firmly follow the new path of independent innovation and development of aero engines, and ensure that China's domestically made aircraft will use a stronger 'Chinese heart' in the future," he said.

One of Li's primary work principles is to "never give up before all problems are solved." In the last decade, Li, together with his colleagues, made use of various methods, including 3D simulation, to elaborately lay out processing plans for different products in accordance with their characteristics, efficiently increasing assembly quality and reducing the production period.

A typical example of the class implementing the principle is the aero engine accessory case. In the past, the case needed to be held together by several people when trying to install it in the belly of the engine, which is difficult and inefficient. This problem greatly bothered Wen Shangzhi, the current leader of the class. To solve it, Wen and his team members made use of their spare time to discuss, search materials, and conduct experiments, finally creating a new method, which obtained certification from experts and effectively improved installation efficiency.

It is in this way that the Li Zhiqiang Class found solutions and overcame obstacles one by one over the last decade, by inventing new methods, new technologies, and new tools. In total, the team solved 52 technical problems in scientific research and assembly, independently developed 312 tools and obtained more than 50 invention patents, the Global Times learned from the corporation.

When two J-20 fighter jets appeared the sky on the hot and humid opening day of the Airshow China 2021, on September 29 in Zhuhai, South China's Guangdong Province, not many spectators fully understood what they had just witnessed.

The two jets started their flight performance with a low tandem flyby above the air show site. Then, one of the aircrafts drastically pulled up and soared into the sky, while the other pulled left and performed a tight spiral maneuver before vanishing into the clouds, in a display of the aircraft's outstanding power and maneuverability.

Immediately after the flight performance, Senior Colonel Li Jikuan, commander of the J-20s' flight performance, announced at a press conference at the air show that it was the J-20's first public performance after being fitted with domestically built engines.

Experts told the Global Times that the domestically built engines provide more powerful thrust that helps the J-20 in super-maneuverability and supersonic cruise, while the engines' serrated nozzles can improve the aircraft's stealth capability.

Another important aspect of converting to use domestically built engines is that it enables mass production of aircrafts, since there are no import restrictions, experts said.

The J-20 is not the only aircraft to use domestically developed engines. Also at the Airshow China 2021, Tang Changhong, chief designer of the Y-20 large transport plane, announced that the Y-20 would be equipped with two types of domestically developed engines. After being equipped with these engines, the Y-20's capabilities have received a boost, Tang said.

Compared with imported engines, the Chinese engines could boost the Y-20's range, endurance, and cargo capacity by providing more powerful thrust and using less fuel, while also allowing the plane to take off and land on shorter runways, analysts said.

Another key member of the "20 aircraft family," the Z-20 utility helicopter, also uses domestically developed engines.

The developers of the Z-20 told the Global Times in October 2019 that the domestically developed engines are powerful enough to enable the helicopter to fly in low-oxygen plateau regions.

Observers noted that the primary battle aircrafts owned by the PLA had converted to domestically developed engines as of this year, but that does not mean China's continued efforts in aero engine development have reached their goal.

Toward stronger future

In the 2022 edition of the Airshow China, AECC showcased five variants of the Taihang series turbofan engines, which are used by different aircraft.

The Taihang engine has received continued improvements and upgrades, and its performance, reliability, safety, stealth capability, power extraction, environmental adaptability, endurance, and thrust vectoring - among other factors - have all received technical boosts.

This is expected to comprehensively enhance the aircraft's survivability and combat capabilities, and has realized the complete independent support of domestically developed engines.

One of the five Taihang engines on display has a 2D thrust vectoring control nozzle, which attracted the attention of visitors.

Li Gang, the pilot of the J-20 stealth fighter jet's first flight, said in a media interview that he would like to see the J-20 eventually be upgraded with engines with 2D thrust vectoring nozzles.

Thrust vectoring control can greatly enhance the manoeuvrability of an aircraft, usually a fighter jet, by providing thrust directly to a desired direction in addition to using aerodynamics, and this will give the aircraft many tactical advantages in combat, Wei Dongxu, a Chinese military expert, told the Global Times at the event.

An aero engine with a thrust vectoring control nozzle is mechanically and structurally more complex than an engine without one, and this means that thrust vectoring control usually causes a certain level of thrust loss. A 2D nozzle could lose even more thrust than a 3D nozzle. China's development of a turbofan engine with a 2D thrust vectoring control nozzle means the engine has sufficient power to manage the loss of thrust, Wei said.

A 2D nozzle usually has better radar and infrared stealth capability than a 3D nozzle, and that makes the 2D nozzle a generally better option, if the engine itself can provide enough power, Fu Qianshao, a Chinese military aviation expert, told the Global Times.

At Airshow China 2018, a J-10B thrust vector control demonstrator aircraft equipped with an engine with 3D thrust vectoring control nozzle delivered a flight performance. An engine with a 3D thrust vectoring control nozzle was also on display at the Airshow China 2022 as one of the five Taihang variants.

It is widely expected that China will continue to develop more advanced aero engines and use them on its advanced warplanes.

Photos

Related Stories

- Xi sends congratulatory letter to 2023 Beijing Culture Forum

- Xi holds talks with Venezuelan president

- Xi encourages customs workers to better serve nation

- Xi replies to letter from customs workers

- Xi's Imprint on the Era | Xi Jinping's Bicycles

- Xi extends Teachers' Day greetings

- Thread-bound edition of Xi's selected works published

- Army unit urged to improve training, combat readiness

- Xi: Strive for revitalization of northeast

- Xi urges Heilongjiang to firmly grasp strategic position in China's overall development, strive to open new ground for high-quality development

Copyright © 2023 People's Daily Online. All Rights Reserved.