Company in E China’s Shandong a gold medal mat maker, official supplier of Olympics

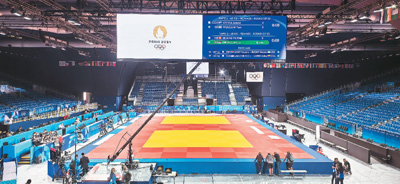

Photos show the interior of the Champ-de-Mars Arena in Paris, France, with the mats in the center made in China. (Photos provided by the interviewees.)

On July 27, in the men’s 60kg judo final, Yeldos Smetov from Kazakhstan won his country’s first-ever Olympic gold medal in judo.

His fist-pumping victory was instantly broadcast across Central Asia and around the world. In the photos of the celebration, beyond the smiling Smetov, the yellow mat he competed on stood out, a mat produced in Leling city, east China's Shandong Province.

“Seeing Olympic champions born on mats we've produced fills me with a unique sense of pride,” says Wang Tao, a 46-year-old employee of Leling’s Taishan Sports Industry Group Co., Ltd. (Taishan Sports), the producer of the Olympic mats.

On the morning of July 23, Wang is at the Taishan Sports mat production workshop, finishing work on a 5-centimeter-thick red mat.

He leaned forward, feet apart, his left hand slightly open to steady the top of the mat, while his right hand held a cylindrical tool which he rolled clockwise along the side of the mat.

“Finishing the edge is an important part of producing the mat. The mat is soft, so the edges need to be compacted for easy assembly,” explained Wang.

The batch of mats he worked on are set to be shipped to Bahrain for the 2024 ISF Gymnasiade.

Workers prepare to install mats at the Champ-de-Mars Arena in Paris, France. (Photos provided by the interviewees.)

Taishan Sports wasn’t always a major international company.

Their story began on one summer afternoon in 1978. A farmer stood atop his own mud-brick house, several meters high, nervously stomping his foot. He clenched his teeth, shouted, and leapt onto the mat below.

It was a 1-meter-by-1-meter mat. This farmer was Bian Zhiliang, the founder of Taishan Sports. His jump was to test the mat’s rebound performance.

Bian had just received a major order to sew 10 new mats for a school in Jinan. The sponge material needed for the mats could only be purchased in Beijing, Shanghai, and Changzhou. After traveling to multiple locations, he gathered the necessary materials. After working tirelessly through many nights, he completed the mats.

Through visual inspection, hands-on testing, personal jumping trials, and estimated standards, Bian continuously improved the performance of his mats, earning praise from the school. Thus, the initial product of Taishan Sports was born.

These days, no one is jumping off houses to test the mats. Using advanced equipment such as drop weight impact testers, scanning electron microscopes (SEM), and 3D printers, Taishan Sports can test and ensure quality with precision.

In the laboratory, researchers use a smart drop hammer impact tester to test the rebound, indentation, and impact force of the mats. According to International Judo Federation standards, each point must be tested 10 times, with the average of the first eight readings taken.

The use of modern technology doesn’t end with just the testing of the mats, but can also be found within the mats themselves.

The mats used in the Paris Olympics feature smart chip technology for the first time. They allow real-time collection of athletes' movement data, providing accurate references for coaching teams to guide training and adjust tactics.

Zhang Wei, general manager of Taishan Sports International Marketing Center, led a team with over a dozen engineers to Paris for the Olympics. They laid out a total of 360 2-meters-by-1-meter mats to cover the 36-meters-by-20-meters competition area using the utmost care and precision.

On July 8, at the production workshop of Taishan Sports Industry Group Co., Ltd. In east China’s Shandong Province, workers inspect newly produced pommel horses. (Xinhua/Zhu Zheng)

Taishan Sports has evolved from being a mere equipment supplier to becoming an event service and one-stop solution provider, playing a role before, during, and after a competition.

To date, Taishan Sports has served nearly 2,000 domestic and international large-scale events, including five Summer Olympics, one Winter Olympics, three Youth Olympics, six World University Games, six Asian Games, and nine National Games.

For the Paris Olympics, in addition to providing mats, Taishan Sports also supplied sports equipment for wrestling, boxing, judo, cycling, taekwondo, gymnastics, and other events, as well as pre-competition training equipment and indoor fitness equipment for the Chinese national team’s training base.

“The Chinese sports industry is transitioning from ‘Made in China’ to ‘China Smart Manufacturing’ and ‘Chinese Service’,” exclaimed Zhang.

On July 8, at the production workshop of Taishan Sports Industry Group Co., Ltd. in east China’s Shandong Province, workers manufacture gymnastics equipment. (Xinhua/Zhuzheng)

Photos

Related Stories

- China claims historic rhythmic gymnastics group all-around title at Paris 2024

- Olympics | Cao Yuan's platform win completes China's clean sweep of diving golds in Paris

- Olympics | China retains women's table tennis team title at Paris 2024

- Olympics | Chinese diver Cao retains his 10m platform title at Paris 2024

- Olympics | Boxing tournament ends with China, Uzbekistan golds

Copyright © 2024 People's Daily Online. All Rights Reserved.