Over 750,000 SMEs in Guangdong employ cloud systems for higher-efficiency production

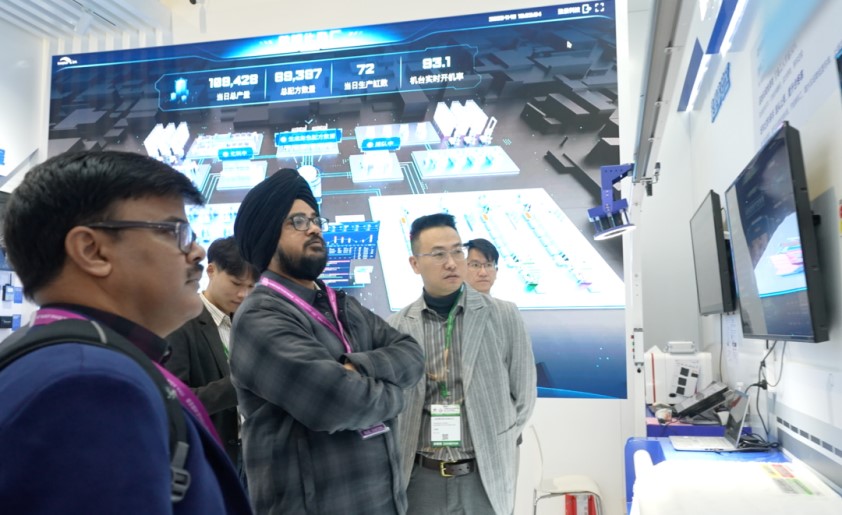

Foreign merchants visit the exhibition area of Guangzhou Zhijing Information Technology Co., Ltd. at the ITMA ASIA + CITME held in Shanghai, November 2023. (Photos provided by Guangzhou Zhijing Information Technology Co., Ltd.)

Guangdong province in south China has been accelerating the digital, networked and intelligent development of the manufacturing sector in recent years, leveraging technological transformation to upgrade traditional manufacturing industries such as textile and home appliance.

As a major production base of the textile and garment industry, Guangzhou, capital of Guangdong province has encouraged a number of industrial internet platforms to help small- and medium-sized enterprises (SMEs) transition to cloud-based systems and services, including Guangzhou Zhijing Information Technology Co., Ltd. (GZIT), a Guangzhou-based company that uses digital technologies to streamline textile operations.

The company has developed an intelligent platform that assists garment manufacturers find proper fabric suppliers. The platform gathers massive market information and can quickly search for desired items based on actual demands.

Shi Daqing, general manager of a garment company in Dongguan, Guangdong province, is a beneficiary of the platform. "In the past, I had to search in fabric markets for days every time I came to Guangzhou to procure supplies. Now, with online fabric selection, it only takes a few minutes to find the fabrics we want," said Shi, who has been engaged in the garment business for more than 20 years.

According to Li Yaping, co-founder and senior vice president of GZIT, the company, leveraging big data, Internet of Things and other cutting-edge technologies, has launched multiple smart cloud platforms that cover all sectors of the garment industrial chain, from fabric production to procurement, and from apparel design to sales.

Li told People's Daily that it generally cost over half a month to design a piece of clothing in the past, which needed multiple procedures such as graphic design, pattern making, cutting and sample making.

Photo shows an automated weaving machine equipped with a real-time intelligent quality-check system. (Photos provided by Guangzhou Zhijing Information Technology Co., Ltd.)

However, the cycle has been shortened to just minutes thanks to an intelligent apparel design platform independently developed by GZIT, which can rapidly generate virtual samples based on preset styles and preferences.

In a smart textile park of GZIT in Yibin, southwest China's Sichuan province, the company employs a real-time intelligent quality-check system.

Many defects of fabrics couldn't be spotted by manual inspections, and now with the fully automated quality-check system, over 99 percent of the products are qualified, said Li Peifeng, head of the smart textile park.

"Each roll of the fabrics comes with a quality-check report and a QR code, which enable full traceability of production information along the chain," he told People's Daily.

Since its establishment in 2014, GZIT has continually expanded its business scope, serving more than 50,000 enterprises in the textile and apparel industry both inside and outside Guangdong province with digital technologies.

"Cloud" services give a big helping hand to SMEs, which is deeply recognized by Chen Kai, general manager of a textile company in Foshan, Guangdong province.

Photo shows a smart brain system for dyeing. (Photos provided by Guangzhou Zhijing Information Technology Co., Ltd.)

"We all know the benefits of digitalization, but everything about it, from R&D to equipment upgrade, costs money. Cloud services allow us small businesses to achieve significant outcomes with minimal investment," Chen noted.

Today, Chen's company can pay to use GZIT's intelligent systems and enjoy tangible benefits of technological transformation. "The systems monitor equipment operation in real time, reducing abnormal downtime by 35 percent and boosting overall efficiency by 30 percent," Chen said.

As more and more companies adopted its services in recent years, GZIT built a cloud platform that coordinates upstream and downstream production.

"Downstream apparel manufacturers place orders, the platform assigns them, and upstream textile firms take them," said Li. "Through cloud-based management, we can rapidly match demands and supplies, thus promoting efficient production."

Li is quite optimistic about GZIT's future development. "Apart from servicing upstream and downstream enterprises, we are now integrating them to make the industrial chain more resilient and competitive!"

Zou Yongbing, chief economist of the Department of Industry and Information Technology of Guangdong province, said that in recent years, the province has introduced and cultivated over 400 outstanding industrial internet platform companies and service providers including GZIT. Collectively, they have driven digital transformation for over 30,000 industrial enterprises above designated size and enabled over 750,000 SMEs to adopt cloud solutions.

Photos

Related Stories

- New factory of Coca-Cola bottler breaks ground in China's Guangdong

- Intercity rails in Guangdong begin trial operations

- Torrential rains lash multiple cities in China's Guangdong

- Trending in China | Traditional morning tea in Guangdong

- China unveils new measures to facilitate opening-up, international exchanges

Copyright © 2024 People's Daily Online. All Rights Reserved.