How innovation, industrial chain upgrading reshape China's slipper manufacturing

Slippers are showcased in an exhibition hall of Xiangtai Footwear in Jinjiang, southeast China's Fujian province. (Photo from Fujian Daily)

Neikeng township in Jinjiang, southeast China's Fujian province, may sound unfamiliar to many, yet on average, one in every eight people worldwide wears a pair of slippers produced there.

This township is home to nearly 2,000 enterprises engaged in the slipper manufacturing business. It produces over 1 billion pairs of slippers each year, with total annual output value exceeding 30 billion yuan ($4.32 billion). On a broader scale, the city of Jinjiang, with Neikeng as its production core, exports about 40 pairs of slippers every second to global markets.

At Fujian Zhenlong Shoes Co., Ltd., local manufacturer Zhang Zhenxian's phone buzzes continuously with international orders in English and French. Nearby, Musa, an African procurement specialist, scans a QR code on a slipper sole, instantly accessing product specifications, 3D diagrams, and compliance certificates. With a few tablet swipes, he customizes color and pattern in real-time. Within 30 seconds, a 3,000-pair order for Nigeria syncs to a smart factory 5 kilometers away.

What began as ordinary household footwear now sweeps global markets with remarkable speed. From Southeast Asian streets to American apartments, Chinese-made slippers have become everyday fashion items abroad.

In Yiwu in east China's Zhejiang province, known as the world's capital of small commodities, livestream e-commerce brings traditional manufacturing to global audience.

During a Tena Footwear livestream hosted by a Malaysian team, hexagon-patterned anti-slip sandals (priced at ¥120) demonstrated extraordinary grip on oil-coated glass and 45-degree steel slopes. Over 40,000 pairs sold in just three hours.

Tena Footwear, with two decades of export experience to Europe, the U.S., Japan, and South Korea, recognized Southeast Asia's livestream boom early. "Partnering with local agencies," said company head Liu Bo, "we've achieved consistent year-on-year sales doubling in these markets."

Small products can open up vast markets. Market research shows that the global slipper market reached $30 billion in 2024, up 7.2 percent year on year, making it one of the fastest-growing categories in international consumer trade.

As a major supplier of slippers, China's slipper industry is upgrading toward smarter manufacturing, healthier materials and greener production. Output and exports continue to rise steadily, with products sold to diverse markets including Europe, the United States, Southeast Asia and the Middle East, cementing slippers as a strong segment of China's light-industry exports.

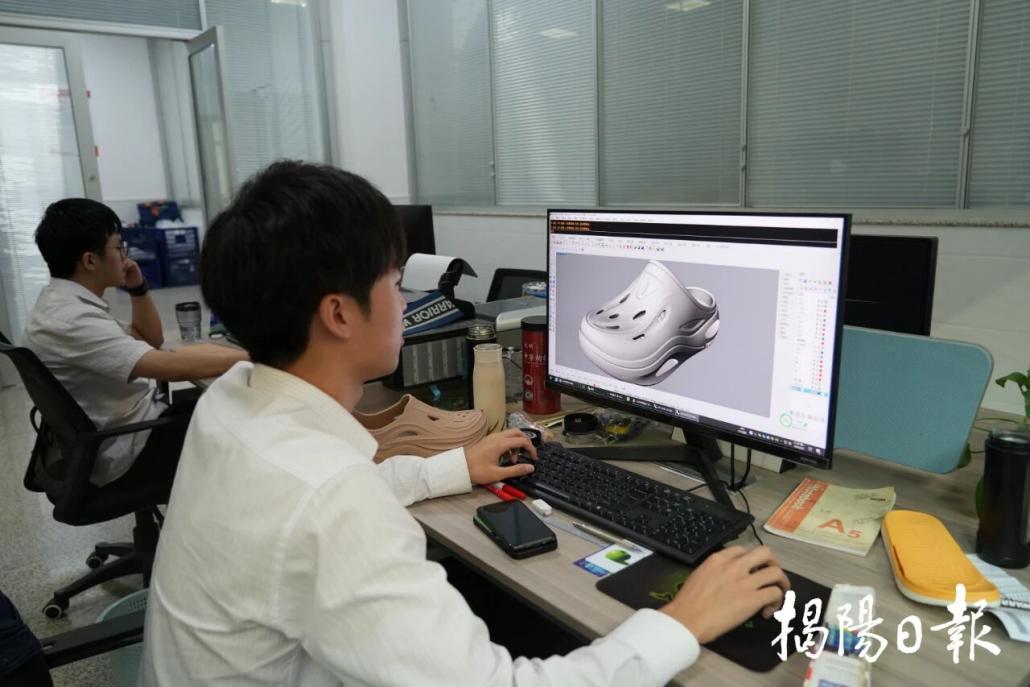

A new model of sandals is designed in a footwear company in Jieyang, south China's Guangdong province. (Photo from Jieyang Daily)

Behind the global appeal of Chinese slippers lies technological innovation and comprehensive industrial upgrading.

In a dust-free laboratory of Xiangtai Footwear in Jinjiang, vice general manager Zhang Zhenjie placed an ordinary-looking white material into a freezer set at minus 20 degrees Celsius. An hour later, when it was taken out, the material still felt warm to the touch.

"This is a phase-change temperature-regulating material," he explained. "It absorbs and releases heat, keeping feet within a comfortable temperature range."

Originally developed for spacesuits, the technology is now used in outdoor slippers designed for Nordic markets, priced several times higher than conventional products.

Laboratories have become the essential core of Jinjiang's leading footwear manufacturers.

In one example, Xiangtai Footwear, in collaboration with the Fujian Institute of Research on the Structure of Matter under the Chinese Academy of Sciences, has developed an antibacterial and odor-resistant EVA (ethylene vinyl acetate) composite material that boosts slipper's bacterial inhibition rate to 99 percent.

Meanwhile, another local enterprise extracts fiber from Fujian-grown juncao grass to produce biodegradable, environmentally friendly shoe materials.

Over the past five years, the number of invention and utility model patents authorized in Jinjiang's slipper industry has grown by more than 30 percent annually on average.

A foreign merchant buys sandals at the China Import and Export Fair. (Photo provided by Jieyang Shenglubao Footwear Ltd.)

Strong supply-chain support and rapid-response mechanisms also enable Chinese slipper makers to swiftly capture shifts in global demand.

In a flexible intelligent manufacturing workshop of Jiajiale, a footwear brand based in Fujian, a single production line tells a global story: the first 30 pairs feature Nordic minimalist patterns for indoor sock slippers; the next 50 pairs are beach sandals adorned with Southeast Asian floral motifs; the final 20 pairs are functional slippers designed for the Japanese market, with subtle arch support.

This flexibility is powered by full digital transformation. Orders placed through cross-border e-commerce platforms are transmitted directly to a manufacturing execution system (MES), which automatically breaks down processes, calculates material requirements and schedules production. Automated guided vehicles (AGVs) deliver raw materials of different colors and textures precisely to each workstation.

According to brand founder Chen Zhihua, digital systems have shortened new product development cycles from 45 days to just 15 days, while reducing the minimum order quantity from 3,000 to 300 pairs.

As competition intensifies, Chinese slipper companies are increasingly focusing on brand development. In 2024, the average export price of Chinese slippers featuring homegrown brands or IP co-branding rose significantly, reflecting a strategic shift toward branding to strengthen premium pricing. At the same time, the rise of cross-border e-commerce has provided smoother and more accessible channels for small and medium-sized enterprises to expand overseas.

From producing purely functional items to creating fashionable products, from competing on low prices to delivering premium offerings, and from unbranded sandals to distinct brand identities, the global journey of Chinese slippers vividly traces the transformation of "Made in China." This once-humble household product continues to write its remarkable story in markets across the world.

Photos

Related Stories

- Chinese heating appliances gain global traction amid seasonal demand

- Smart factories across China explore new models of manufacturing

- China steps up efforts to advance AI-assisted manufacturing

- China in elite global manufacturing club

- China becomes the world's fourth manufacturing power

- China's robot industry doubles revenue in five years

- China's high-tech manufacturing sector reports robust profit growth from Jan-Oct

- Rationale behind China's commitment to keeping appropriate share of manufacturing in national economy

- Chinese products bring coolness to European consumers

- Yiwu's global buying spree reflects broader trends in China's foreign trade

Copyright © 2026 People's Daily Online. All Rights Reserved.