Chinese brands forge ahead toward high-quality development

In recent years, China has attached great importance to enhancing the strength of indigenous brands and ramped up efforts to accelerate the shift from “Made in China” to “Created in China” and from “Chinese products” to “Chinese brands”.

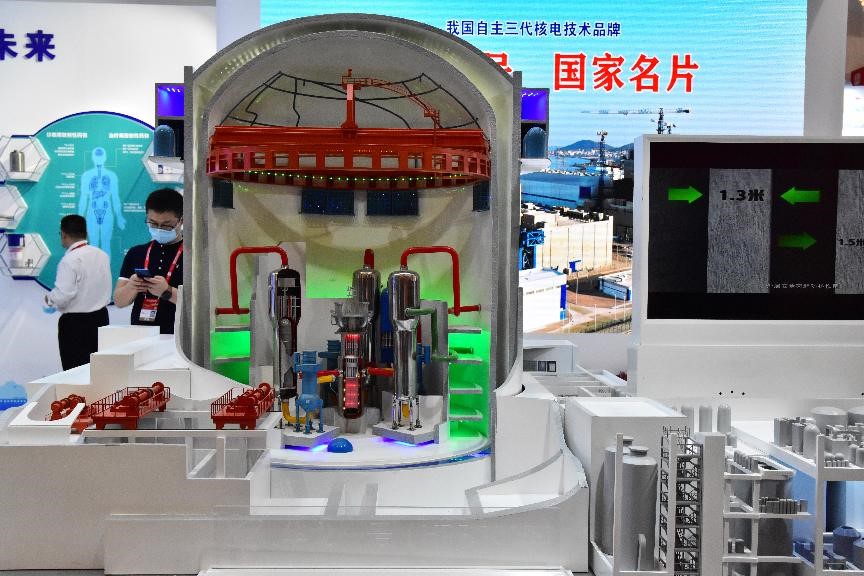

Photo taken on May 10, 2021 shows a model of nuclear reactor Hualong One exhibited by China National Nuclear Corporation at an expo on China indigenous brands held in east China’s Shanghai. (People’s Daily Online/Zhou Dongchao)

Chinese brands have delivered eye-catching performance in both international and domestic markets this year. A total of 143 Chinese companies entered the 2021 Fortune Global 500 list, making China top the ranking. During this year’s Singles’ Day shopping festival in China, the volume of transaction of more than 100 domestic brands on China’s e-commerce giant JD.com surged over eight times year on year, while China’s leading search engine Baidu witnessed the greatest increase in the number of domestic products-related searches in nearly three years.

More and more Chinese enterprises have built their brands and improved their core competitiveness by making innovations, creating such important products as a smart jacking platform that is the first of its kind in the world, the world’s largest rectangular shield tunneling machine, and the world’s thinnest stainless steel foil.

Many Chinese brands have changed their development ideas and started to explore the path of collaborative innovation.

Leading Chinese home appliance brand Galanz has joined hands with American household appliance brand Whirlpool, through which the two home appliance giants are expected to further enhance their mutual complementarity and generate more fruits of innovation.

At the 130th China Import and Export Fair, commonly known as the Canton Fair, held in October this year in Guangzhou, capital of south China’s Guangdong province, they exhibited a solution to whole-house smart home appliances.

A visitor tries 5G-empowered remote driving technology developed by Chinese bus maker Yutong at the company’s exhibition booth at an expo on China indigenous brands, one of the 2021 China Brand Day events in Shanghai, May 10, 2021. (People’s Daily Online/Long Wei)

Galanz has established research and development (R&D) centers and branches in more than 10 countries around the world. Its products have been sold to nearly 200 countries and regions.

In January this year, China’s first nuclear power unit using Hualong One, a domestically-designed third-generation nuclear reactor, entered commercial operation, a result of nearly 20 years of hard work of the R&D team of China National Nuclear Corporation.

Thanks to its achievements in nuclear power technology represented by the Hualong One nuclear reactor, Karachi Nuclear Power Plant Unit-2 (K-2) in Karachi, Pakistan, and the high-temperature gas-cooled reactor of Shidaowan nuclear power plant in east China’s Shandong province, China has become one of the frontrunners in the field of the third-generation and the fourth-generation nuclear power technologies this year.

China’s homegrown sportswear brand Anta is intensifying efforts to build an integrated warehousing and distribution network using both online and offline means. On the one hand, by promoting the application of digital technologies in logistics services, the company has improved user analysis and managed to realize precise distribution of inventory. On the other hand, it has widely used automatic guided vehicles (AGVs) and other emerging machines and systems offline, raising the efficiency of parcel sending by 30 percent.

During this year’s Singles’ Day shopping festival, Anta sent off more than 13 million parcels and offered better shopping experiences to consumers by leveraging smart logistics.

Quality is the lifeblood of brands. Ensuring quality safety and improving the level of quality is an important precondition for the high-quality development of Chinese brands.

Inner Mongolia Yili Industrial Group Co., Ltd., a leading Chinese dairy producer, innovatively developed and upgraded a smart ranch big data analysis and application platform, which enables farm workers to check dynamic information about cows in real time and feed them precisely according to their needs, thus ensuring science-based diet and healthcare for cows as well as the production of high-quality milk.

In a lab of the technological innovation and R&D center of Guangdong HEGII Sanitary Wares Co., Ltd., a major sanitary ware production company in China, more than 700 reliability testing platforms have been running around the clock to make sure the company’s products pass the most rigorous tests.

The company’s efforts to improve product quality have been proven rewarding. Its sheet material can remain intact after being soaked in hot water at 80 degrees Celsius for 109 hours, while the coating it produces still shows outstanding water repellency performance after 100,000 times of scrubbing.

“Quality is the top priority of HEGII. Our persistence on ensuring high quality of our products creates broader space for development,” said Ding Wei, chief executive officer of the company.

Many Chinese companies have actively made contributions to the implementation of China’s rural vitalization strategy.

An employee of a subsidiary of Maanshan Iron and Steel Co., Ltd. conducts quality control check on high-quality special steel products, May 14, 2021. (People’s Daily Online/Luo Jisheng)

Inner Mongolia Yili Industrial Group Co., Ltd., for one, has organized training sessions for dairy farmers, and helped a cumulative total of five million households shake off poverty.

By tapping into the endogenous culture and carrying out protective development of intangible cultural heritage in rural areas, Overseas Chinese Town Holdings Company (OCT Group) has significantly boosted the development of villages.

Many companies in the country have played important roles in the front line of the country’s endeavors to realize the goal of peaking its carbon emissions by 2030 and achieving carbon neutrality by 2060.

China’s State Power Investment Corporation (SPIC) has put into operation the country’s first “zero carbon” commercial heating project using nuclear energy in Haiyang city, Shandong province.

The project can save 100,000 tons of coal every heating season, which is equivalent to cutting carbon dioxide emissions by 180,000 tons and sulfur dioxide emissions by 1,188 tons, greatly improving the atmospheric environment and marine ecological environment of Haiyang city in the heating season.

With high-quality products, great enthusiasm for innovation, and a strong sense of responsibility, Chinese brands are bound to grow increasingly competitive and exert far-reaching influence on the international market along their path to high-quality development in the new stage, said Jiang Xiaojuan, dean of School of Public Policy and Management, Tsinghua University.

Photos

Related Stories

- Chinese brands in various sectors witness significant growth in sales

- Chinese brands increase presence on global playing field: report

- Rejuvenation of Chinese brands boosts popularity among young consumers

- 'Made in China' cannot easily be replaced

- 'Made in China' embraces improved quality, expanded market

- Chinese brands quicken pace to go global

Copyright © 2021 People's Daily Online. All Rights Reserved.