Snapshot photo of the paper published on Matter

It seems that 3D printers can make everything nowadays: from a house to a piece of cloth.

A group of Chinese researchers from Tsinghua University have announced a new breakthrough in wearable electronics, weaving electronics into clothes with 3D printing technology, according to a paper published on Mar. 28 on Matter, a new journal from Cell Press.

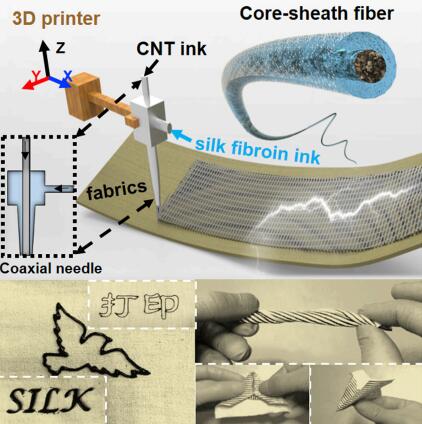

Led by Zhang Yingying, a professor from the Department of Chemistry at Tsinghua, the researchers used a 3D printer equipped with a coaxial nozzle to print fibers on textiles. With the coaxial nozzle, the composition of fibers and functional design can be better guaranteed. For proof of concept, they chose two types of “inks”: one with carbon nanotubes as the conducting cores and the other with silkworm silk for insulating sheath.

The two types of “inks” were simultaneously injected and created different patterns on the textile: the Chinese characters for “print,” the English word “silk,” and an image of a pigeon.

Different from previous methods in e-textile, this new design can integrate electronic fibers on the fabric at the same time when the e-fibers are made, which greatly improves the production efficiency of the electronic fabric. It is also more convenient and scalable for wearable electronics, as it can select multiple ink combinations and integrate different functional units into the fabric at once.

“We hope this work will inspire others to build other types of 3D printer nozzles that can generate designs with rich compositional and structural diversity and even to integrate multiple co-axial nozzles that can produce multifunctional e-textiles in one-step,” Zhang was quoted as saying.

Zhang added that the team plans to design flexible, wearable hybrid materials and electronics with more properties. They also aim for new techniques to produce smart wearable systems with integrated functions, such as sensing, actuating, and communicating.

Fire brigade in Shanghai holds group wedding

Fire brigade in Shanghai holds group wedding Tourists enjoy ice sculptures in Datan Town, north China

Tourists enjoy ice sculptures in Datan Town, north China Sunset scenery of Dayan Pagoda in Xi'an

Sunset scenery of Dayan Pagoda in Xi'an Tourists have fun at scenic spot in Nanlong Town, NW China

Tourists have fun at scenic spot in Nanlong Town, NW China Harbin attracts tourists by making best use of ice in winter

Harbin attracts tourists by making best use of ice in winter In pics: FIS Alpine Ski Women's World Cup Slalom

In pics: FIS Alpine Ski Women's World Cup Slalom Black-necked cranes rest at reservoir in Lhunzhub County, Lhasa

Black-necked cranes rest at reservoir in Lhunzhub County, Lhasa China's FAST telescope will be available to foreign scientists in April

China's FAST telescope will be available to foreign scientists in April "She power" plays indispensable role in poverty alleviation

"She power" plays indispensable role in poverty alleviation Top 10 world news events of People's Daily in 2020

Top 10 world news events of People's Daily in 2020 Top 10 China news events of People's Daily in 2020

Top 10 China news events of People's Daily in 2020 Top 10 media buzzwords of 2020

Top 10 media buzzwords of 2020 Year-ender:10 major tourism stories of 2020

Year-ender:10 major tourism stories of 2020 No interference in Venezuelan issues

No interference in Venezuelan issues

Biz prepares for trade spat

Biz prepares for trade spat

Broadcasting Continent

Broadcasting Continent Australia wins Chinese CEOs as US loses

Australia wins Chinese CEOs as US loses