Boeing faces a public test of the carbon-composite technology used in its 787 Dreamliner following a fire aboard one of its planes at London's Heathrow airport.

British investigators said the Ethiopian Airline's lithium-ion batteries likely did not cause the fire on Friday, allaying fears about a return of the problem that grounded the Dreamliner for more than three months earlier this year, when one battery caught fire and another overheated.

But the visible scorching on the top rear of the fuselage of the 250-seat plane puts a major innovation of the 787 - its lightweight, carbon-plastic composite construction - under the spotlight.

The key question: Can the burned plane be fixed easily and at a reasonable cost?

While composites have been used in aerospace for decades, the 787 is the first commercial jetliner built mainly from carbon-plastic materials, whose weight savings, combined with new engines, are supposed to slash fuel costs by 20 percent and operating costs by 10 percent.

Boeing engineers also added a weight-saving electrical system that was sorely tested when its lithium-ion batteries overheated on two 787s in January. The system also suffered a fire in 2010 during the plane's test phase.

The two systems are supposed to put Boeing at least a decade ahead of its rivals in the way aircraft are designed, built and operated.

Now they are both being tested again at a time when the company is designing new planes and building up its factory production to fill a record book of orders.

Boeing declined to comment other than to say it is cooperating with the investigation of the fire.

Such extensive composite repairs have not previously been performed on an operating commercial plane. So the Ethiopian Airline fire is the first chance airlines, financiers and competitors will have to see a real example of how and at what cost the repair can be done.

Carbon-composite technology and repair have been in use much longer than lithium-ion batteries. Boeing and others have had carbon fiber in military planes, such as the B2 stealth bomber, for more than 25 years.

The 787's composite skin can be patched by grinding out the damaged section, applying fresh layers of fiber and resin and then curing with heat under vacuum pressure, according to a Boeing engineer with knowledge of the process.

The work can be done on site, and repair stations have been learning to make repairs to service the plane around the world.

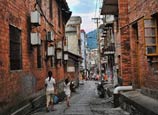

Migrant workes' high incomes not that rosy

Migrant workes' high incomes not that rosy

![]()