China’s manufacturing accelerates industrial digitalization

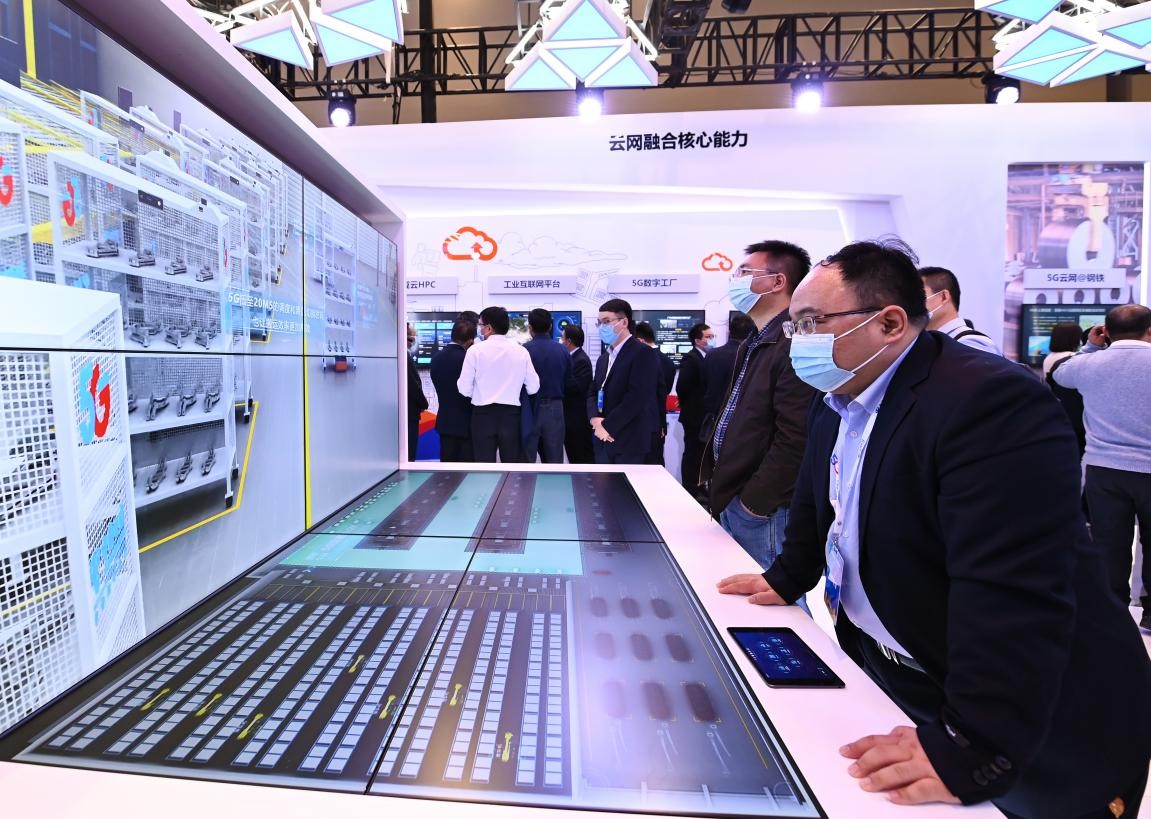

The 2020 China 5G + Industrial Internet Conference is held in Wuhan, central China's Hubei province on Nov. 19, 2020. (Photo by Zhang Canlong/ People's Daily Online)

China has seen accelerated digital transformation of industries and rapid process of software autonomy and control in the first half of this year.

The revenues in industrial software products hit 110.7 billion yuan ($17.13 billion) in the first six months, growing 20 percent from a year ago. More than 70 million units of devices have been connected to industrial internet platforms. There was also a steady rise in the digitalization of key processes and the application of digitalized designing tools.

Expanding application scenarios, digging into the potential of industries and completing industrial ecology, Chinese industrial internet is embracing rapid development.

At the plant of Airbus (Tianjin) Final Assembly Company in north China's Tianjin municipality, every worker that enters designated production areas will be scanned by 5G-powered cameras that are able to identify whether the workers are wearing safety helmets or have left their tools at these areas.

This is a typical scenario enabled by the "collaboration" between 5G technology and industrial internet. "Aircraft manufacturing involves many precision parts and complex devices. Even the tiniest error is not allowed. Manual inspection in the past cost huge time and energy, and sometimes couldn't remove all errors," said Zheng Lina, an employee of the Airbus (Tianjin) Final Assembly Company.

She compared the industrial internet-5G combination to a safety inspection expert that stands by anytime, which not only substantially reduces cost, but also improves the safety of production.

Technicians from a machinery company in Beibei district, southwest China's Chongqing municipality check the operation of a workshop on an industrial internet platform, Sept. 15, 2020. (Photo by Qin Tingfu/ People's Daily Online)

At a smart welding workshop of XCMG Machinery, a leading heavy machinery manufacturer in China, nine smart production lines are employed. They have completed crane orders worth nearly four billion yuan.

"The collaboration between 5G and industrial internet enables massive devices made by different manufacturers and brands to be connected to platforms, which achieves maximum interconnectivity among the devices," said Li Zhongfu, head of XCMG Machinery's informatization management division.

The integration of 5G and industrial internet makes it possible to track real-time operation data of production devices, which improves production efficiency by 20 percent, said Li. It also sends back operating parameters to the manufacturers, so that they can offer remote diagnosis services for their clients.

The collaboration between 5G technology and industrial internet will become a major "battlefield" for China's industrial digitalization, said Wang Zhiqin, vice president of China Academy of Information and Communications Technology.

According to him, nearly 1,600 5G-industrial internet projects have been completed, covering over 20 important sectors of national economy. Besides, 5G-industrial internet collaboration is reaching more manufacturing industries from the pioneering aviation, steel, mining and port industries, Wang added.

A 5G-powered autonomous forklift works in an unattended warehouse of retailing giant Suning in Nanjing, east China's Jiangsu province, Aug. 11, 2020. (Photo by Fang Dongxu/People's Daily Online)

At a workshop of Jiaxing Xinyuan Textile Co., Ltd., east China's Zhejiang province, there is a small black box that connects 270 spinners, 108 two-for-one twisters and other supporting facilities to a "cloud brain."

The cloud platform has improved spinner efficiency by four percent and average per capita output by nine percent, and lowered management cost by five percent, said Luo Yuan, general manager of the textile company. "It not only improves product quality, but also guarantees on-time delivery of products," Luo noted.

"Most of the medium- and small-sized textile companies still rely on manual labor for production and management," said Zhang Pei, senior product manager of Zhijing Technology, the provider of the cloud platform. The platform has served more than 5,000 textile enterprises and is connected to over 400,000 spinners, which account for 26 percent of the total capacity of China's textile industry. It has saved relevant enterprises more than one billion yuan.

An official with the Ministry of Industry and Information Technology noted that China will foster a batch of industrial internet system solution providers in the next five years, make them leading players in the sector that promote synergetic innovation among large, medium and small enterprises, and help small and medium sized enterprises enhance their capability of digital transformation.

Photos

Related Stories

Copyright © 2021 People's Daily Online. All Rights Reserved.