More and more factories in China are using robots on the assembly lines to replace workers who demand high salaries.

Factories have struggled to keep up with overseas orders due to the rising labour cost and instead opted for machines, according to a report by China Central Television Station (CCTV).

One boss, from Guangdong Province, said his factory started using robots after they realised the labour cost in China was twice as much as that of Mexico and four times as that of India.

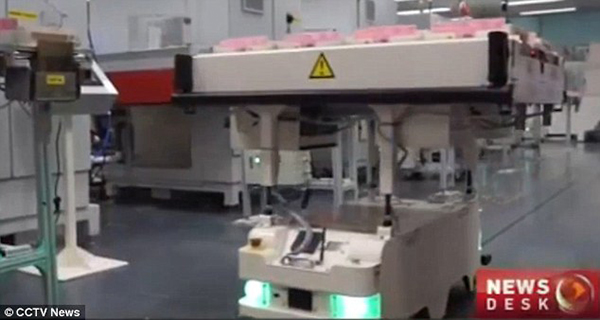

Footage from CCTV shows how two Chinese factories have used robots to replace workers

More and more Chinese factories have opted for machines in order to cut labour cost

One factory, which produces lenses for German brand Carl Zeiss in Guangzhou, replaced 70 workers with robots between 2012 and 2015 and managed to increase the output

A reporter from CCTV visited two robot-equipped factories, both situated in Guangdong Province.

The region, located in southern China, is well-known for its large number of factories handling overseas orders for famous brands including Disney.

One factory, which produces lenses for German brand Carl Zeiss in Guangzhou, started using robots four years ago in a bid to improve productivity and to cut costs.

Its manager Zeng Zhiyong told the reporter that they were informed in 2012 that China's labour cost is twice more expensive than Mexico's and four times more expensive than India's.

Zeng told CCTV: 'We were very surprised at this huge gap and started to think of how to improve productivity.'

Between 2012 and 2015, Zeng cut down the number of workers by 70 people - from 440 to 370 - but managed to increased the output from four million to five million lenses per year.

Rongxin Packaging Corporation produces 1.8 million cans per day.

Impressively, the entire production process does not involve any workers, its general manager Ji Yonghong told CCTV.

However, Ji said the factory has employed younger, more skilled and better-educated workers to maintain the machines and control the quality.

Automated machine, tools and robotics have been marked by Chinese authority as one of the 10 priority sectors of China in the next nine years

Many factories in China have started replacing the workforce with modern technologies

China became the world's largest market for industrial robots in 2013. According to People's Daily Online, more than 20 per cent of the world's industrial robots are purchased by China.

Last year, the Chinese authorities named automated machine, tools and robotics as one of the 10 priority sectors in the 'Made in China 2025' plan, a 10-year plan unveiled by China's State Council in a bid to transform China 'from a manufacturing giant into a world manufacturing power'.

This has prompted many factories in China to start replacing the workforce with modern machines.

Foxconn, the Taiwanese company which assembles iPhones and iPads, has also brought in machines to replace its 60,000 workers in one of its branches in southern China.

The robots took over repetitive tasks and took the place of more than half of the factory's 110,000-strong workforce.

While a growing number of Chinese factories are upgrading its production with high technology, the working conditions of some of them remain worrying.

Previous MailOnline investigations discovered that impoverished men and women from rural areas work 12-hour shifts for £250 a month in Pegatron, a factory in suburban Shanghai which produces Apple products.

While in southern China's Dongguan city, migrant workers toil 11 hours a day and six days a week making Frozen toys for Disney at a factory.

Shenzhen seizes 549 tons of illegally smuggled clothing

Shenzhen seizes 549 tons of illegally smuggled clothing Chinese actor Wang Baoqiang divorces wife, fires manager

Chinese actor Wang Baoqiang divorces wife, fires manager New hovercrafts debut in landing exercise

New hovercrafts debut in landing exercise Home-made plane completes test flight in Chicago

Home-made plane completes test flight in Chicago Huangluo: China's 'long hair village'

Huangluo: China's 'long hair village' Spectacular bridge with one of the tallest piers in the world

Spectacular bridge with one of the tallest piers in the world Magnificent view of Hukou Waterfall

Magnificent view of Hukou Waterfall Woman sets Guinness World Record with 17-month-long pregnancy

Woman sets Guinness World Record with 17-month-long pregnancy A glimpse of Stride 2016 Zhurihe B military drill

A glimpse of Stride 2016 Zhurihe B military drill Top 10 livable Chinese cities

Top 10 livable Chinese cities Top 20 hottest women in the world in 2014

Top 20 hottest women in the world in 2014 Top 10 hardest languages to learn

Top 10 hardest languages to learn China’s Top 10 Unique Bridges, Highways and Roads

China’s Top 10 Unique Bridges, Highways and Roads Carter wrong to blame China for NK nuke issue

Carter wrong to blame China for NK nuke issue Beijing once again vows to renovate the shantytown in its CBD

Beijing once again vows to renovate the shantytown in its CBD New forensic technology helps cops nab serial killer 14 years after last murder

New forensic technology helps cops nab serial killer 14 years after last murder Cross-national marriages meet higher divorce rates due to cultural differences, parenting styles and lack of communication

Cross-national marriages meet higher divorce rates due to cultural differences, parenting styles and lack of communicationDay|Week