General Electric Aviation has put together an engine it boasts is so gigantic that Shaquille O'Neil could comfortably fit inside of it with Kobe Bryant on his shoulders.

Dubbed the largest jet engine in the world, GE9X's front fans span 11 feet in diameter, while its inlet duct measures 18 feet by 12 feet and it can generate 100,000 pounds of thrust.

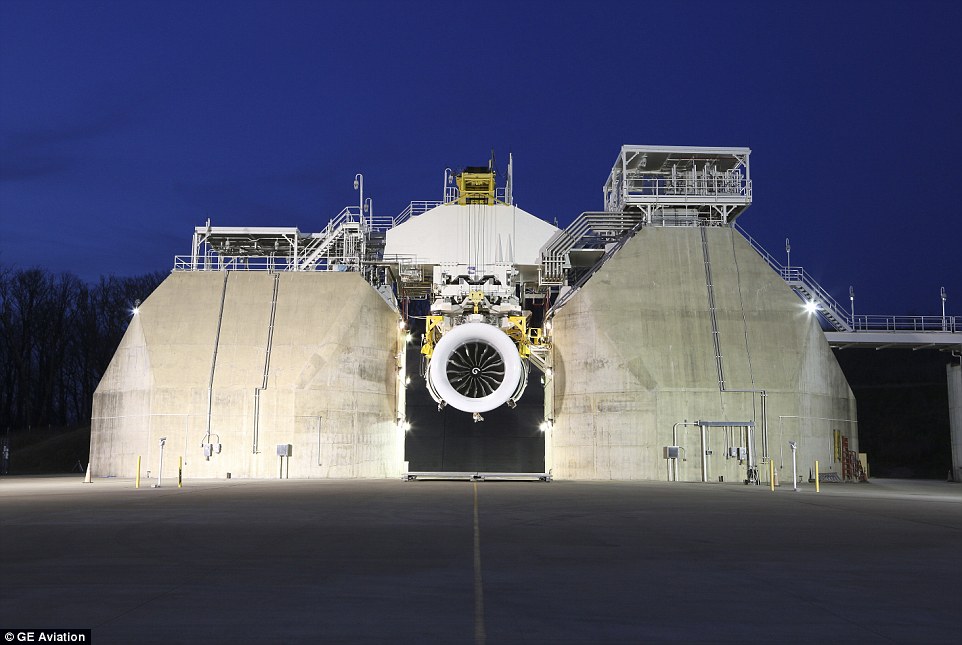

This record breaking engine is the first working prototype that was developed to power Boeing's 777X jet and is currently being tested at the GE's boot camp for engines near Peebles, Ohio.

Dubbed the largest jet engine in the world, GE9X's front fans span 11 feet in diameter, its inlet duct measures 18 feet by 12 feet and can generate 100,000 pounds of thrust. This massive engine is the first working prototype that was developed to power Boeing's 777X aircraft and is currently being tested at the firm's boot camp for engines near Peebles, Ohio

Testing of the engine is seen as a critical step towards development of the 777X aircraft family, a new version of the 777 'mini-jumbo' with up to 406 seats that is due to enter service in 2020.

Boeing asked GE to develop an engine strong enough to power its 777X jet, which has prompted other airlines, including Emirates, Lufthansa and Qatar Airways, to place an order.

In total, the firm has received more than 700 requests for the engines, valuing at $29 million.

The GE9X is made with parts from lightweight and ultra heat-resistant materials known as ceramic matrix composites (CMCs) that can operate at temperatures up to 2,400 degrees Fahrenheit.

This allows the firm's engineers to keep the heat higher inside the engine, without having to burn through fuel or emissions.

'The hotter the engine gets, the more efficient it is,' said GE Aviation spokesman Rick Kennedy in a recent statement.

The advancement in 3D printing has also contributed to this cutting-edge engine, by allowing engineers to create more complex shapes, which were once impossible -- including 3D printed fuel nozzles.

'These tunnels and caves are a closely guarded secret,' said Kennedy.

'They determine how the fuel moves through the nozzle and sprays inside the combustion chamber.'

There are 16 fourth-generation carbon-fiber fan blades in the design that are at the front of the engine and feed air to the 11-stage high-pressure compressor.

According to the firm, no other commercial engine has a pressure ration (27:1) that's higher.

Engineers also installed a fourth fuel tank to keep the engine from going thirsty.

WHAT ARE THE ENGINES MAIN FEATURES?

GE9X's front fans span 11 feet in diameter, its inlet duct measures 18 feet by 12 feet and can generate 100,000 pounds of thrust.

CMCs can operate at temperatures up to 2,400 degrees Fahrenheit.

The engine has 3D printed fuel nozzles.

Includes 16 fourth-generation carbon-fiber fan blades and four fuel tanks.

'The early testing informed the design and manufacturing and allowed us to freeze the product definition and test the total engine as soon as possible.'

Although GE9X has an impressive thrust generator of 100,000, the engine's predecessor, the GE90-115B, holds the record of 127,500 pounds.

Approximately $10 million has been invested by GE to prepare its Peebles Testing Operation for the world's largest engine.

The GE9X is made with parts from lightweight and ultra heat-resistant materials known as ceramic matrix composites (CMCs) that can operate at temperatures up to 2,400 degrees Fahrenheit. This allows the firm's engineers to keep the heat higher inside the engine, without having to burn through fuel or emissions

Approximately $10 million has been invested by GE to prepare its Peebles Testing Operation for the world's largest engine. Testing for the first GE9X began last month and GE Aviation will continue with it for several months in order to verify aerodynamic, thermal and mechanical characteristics of the engine

Testing for the first GE9X began last month and GE Aviation will continue with it for several months in order to verify aerodynamic, thermal and mechanical characteristics of the engine.

Not only has GE built the world’s largest jet engine, it built the world’s first American Jet engine in 1942.

The J31 was the first jet engine to be mass-produced in the United States.

It had a maximum thrust of 1,650 pounds and weight 850 pounds with an rpm of 16,500.

The J31 was developed from the original American-built jet engine, the General Electric I-A (which was a copy of the highly-secret British "Whittle" engine).

The I-A powered the early test flights of the U.S.'s first jet aircraft, the Bell XP-59A Airacomet, and the more powerful J31 was used in production P-59As and P-59Bs.

There are 16 fourth-generation carbon-fiber fan blades in the design that are at the front of the engine and feed air to the 11-stage high-pressure compressor. According to the firm, no other commercial engine has a pressure ration (27:1) that's higher. GE has been testing the new design for the GE9X carbon fiber blades on a scaled-down testing rig at Boeing (pictured)

THE BIGGEST PASSENGER PLANE EVER SEEN

It is set to be the biggest passenger plane ever seen - with a wingspan so big the tips have to be folded up so it can fit into airports.

The Boeing 777-9X will be the largest and most efficient twin-engine jet in the world, the aerospace giant claims - and will begin production in 2017.

320 have already been ordered, the firm says, and will feature a wider cabin and bigger windows than even the firm's 787 Dreamliner.

The plane will have the widest wingspan of any aircraft: 235 feet, 5 inches (71.8 meters), making it wider than four 53-foot (16-meter) semi-truck trailers parked end to end.

It is so big, Boeing has developed hinges on its wingtips. The hinges will fold up, allowing the plane to shorten its wingspan when it's rolling across airport taxiways, the first design of its kind on any commercial airliner.

The hinged wingtips will measure 12 feet, and locking pins will prevent them from folding during flight, Boeing told CNN.

Inside, the 777-9X will seat at least 400 passengers, 34 more than the 777-9X's competitor - the Airbus A350-1000.

The 777-9X cabin will be 16 inches (40 centimeters) wider than the A350-1000, Boeing says, allowing economy-class seat widths up to 18 inches (46 centimeters).

Typical airline seat widths range from 17 to 18.5 inches (43 to 47 centimeters).

The 777-9X's windows will also be 15% larger than competing airliners, Boeing says, and placed at a height that will be eye level for most passengers.

The factory for the plane, in Everett, is big enough to fit 25 football fields inside.

'Building on the success of the 777 and 787 Dreamliner, the 777X will be the largest and most efficient twin-engine jet in the world, unmatched in every aspect of performance,' Boeing says.

'However, performance is just part of the story.

'The cabin interior of the 777X is inspired by the comforts and conveniences of the 787 Dreamliner and includes larger windows, a wider cabin, new lighting and enhanced architecture — all of which will be custom-tailored for a unique 777X experience.

'The 777X is the future of flight unfolding.

'That's a better way to fly.'

The 777-9X will seat at least 400 passengers with a superwide cabin with larger, higher windows when it begins production in 2017.

Day|Week

Female official wearing traditional Han costume to promote local tourism

Female official wearing traditional Han costume to promote local tourism Over 12,000 Runners Seek Medical Care in S China’s Marathon

Over 12,000 Runners Seek Medical Care in S China’s Marathon Six Luxury Sports Cars Totaled after Fail Attempts to Cross China’s Most Perilous Highway Linking SW China’s Sichuan and Tibet

Six Luxury Sports Cars Totaled after Fail Attempts to Cross China’s Most Perilous Highway Linking SW China’s Sichuan and Tibet Incredible Transformation: “Witch Child”Whose Parents Left Him for Dead in Nigerian Makes Speedy Recovery

Incredible Transformation: “Witch Child”Whose Parents Left Him for Dead in Nigerian Makes Speedy Recovery Kenyan woman's crappy photoshopped pictures make her a web celebrity

Kenyan woman's crappy photoshopped pictures make her a web celebrity Magnificent view of E. China's Anhui province

Magnificent view of E. China's Anhui province Global landmarks captured in striking shots

Global landmarks captured in striking shots Thailand Elephants Disguised as Pandas Sparks Debates

Thailand Elephants Disguised as Pandas Sparks Debates College girl dresses as mermaid to mark World Water Day

College girl dresses as mermaid to mark World Water Day J-15 fighters in drill on Chinese aircraft carrier

J-15 fighters in drill on Chinese aircraft carrier