|

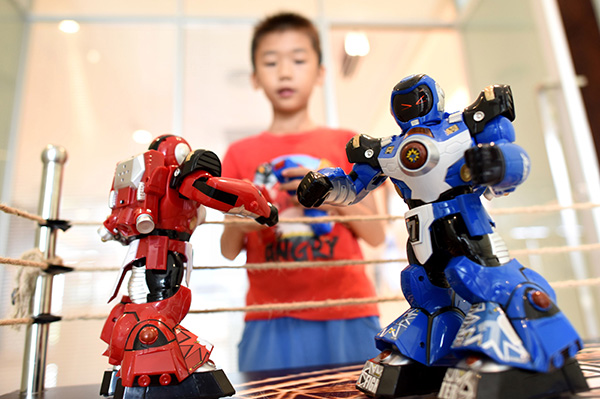

| Robots on display at a newly established supermarket for robots in Foshan, Guangdong province. The store, covering 6,000 square meters, showcases various models produced by Chinese companies. [Photo/Xinhua] |

Do many hands really make work light?

That is what I asked myself when I visited the Pennsylvania, United States-based West Hershey chocolate plant, the largest factory of the American confectionary maker the Hershey Company one month back.

Inside the plant, large-scale and highly automated machines and conveyors far outnumbered humans. Almost every process along the production line, from chocolate tempering, molding, defect detecting to the final wrapping and packaging, was carried out by machines.

Pieces of Hershey Kisses, its signature product, were moving so fast on the conveyer belt that they appeared in a blur. The wrapping machine, as our tour guide told us, can wrap up to 900 Kisses a minute.

I even noticed that a small but sophisticated move-shaking the chocolate bars right before they turn from liquid into solid in the molds so as to prepare them for wrapping-was done by machines.

Toward the end of the production line, giant robotic arms picked up the finished candy, packaged them into cases and hoisted them into the position ready for transportation.

During the tour, I spotted only a dozen workers, most of whom were monitoring the computer screens to ensure the production runs smoothly while some others were doing maintenance work.

"I am really impressed by the high level of automation here at the American plant," Xiao Li, a member of our visiting group and production manager of Shanghai Golden Monkey Food Co Ltd, told me. Her company was acquired by Hershey two years ago.

Xiao told me that her factory in China remains very labor-intensive and one production line will often require about 1,000 workers whereas the entire Hershey factory employs just about 700 workers.

The sharp contrast described by Xiao made me realize that even though economists began to talk about the end of the cheap labor era in China and the trend of moving up the value chain by upgrading the manufacturing capability years ago, the reality could be dimmer.

One problem is that production cost, including labor cost, in China is growing at a faster pace than the improvement of manufacturing capability and product quality, which results in diminishing competitiveness and shrinking profit margin for Chinese manufacturers in the global markets.

Xiao and many other Chinese manufacturers were certainly well aware that one of the alternative solutions lies in automating and upgrading the production process with efficient and sophisticated machines.

But they have been reluctant to do so because it is far too costly to replace workers with machines although they can dramatically improve efficiency and productivity.

"The imported machines often cost hundreds of millions of yuan and the depreciation rate of the equipment is very high," Xiao said. "On the other hand, domestic equipment often fails to meet our standards."

While we talk about transforming the image of "Made in China" products that often associate with the impression of cheap price and poor quality, we need to first think about whether our manufacturers are equipped with the advanced machines that are the prerequisite to produce superb goods.

A recent study by the International Federation of Robotics showed that China has only 30 industrial robots per 10,000 employees in manufacturing industries, while the robotic density of the US is five times larger, Germany 10 times larger and Japan 11 times more.

So, it is not surprising that Chinese leaders have called for substantial investment in robotic research and greater effort to upgrade the country's high-end equipment manufacturing sector that is considered the basis and the touchstone of any country's industrial power.

In Western economies, trade unions have been protesting against the rise of automation as it results in job losses. But we need to be aware that while they are eliminating some bad jobs, they are also expanding and empowering many good jobs.

China is already the world's largest manufacturing power, accounting for one-fifth of global output. But Chinese consumers would still rush to Japan or Europe to buy some of the most basic products in life such as milk powder, toothbrushes and toilet seats.

There is still a long path ahead of China toward becoming a genuine industrial power.

Top 10 nominated designs at BJDW

Top 10 nominated designs at BJDW Fashion show staged in Forbidden City at night

Fashion show staged in Forbidden City at night Construction of HK-Zhuhai-Macao Bridge enters final stage

Construction of HK-Zhuhai-Macao Bridge enters final stage Model of heavy-lift copter makes debuts at Tianjin expo

Model of heavy-lift copter makes debuts at Tianjin expo Art photos of Chinese beauty in Han Chinese clothing

Art photos of Chinese beauty in Han Chinese clothing Stunning photos of air show in China’s V-Day parade

Stunning photos of air show in China’s V-Day parade Models change clothes on street in Hangzhou

Models change clothes on street in Hangzhou Charming Chinese female soldiers

Charming Chinese female soldiers Beauty vs. muscular man

Beauty vs. muscular man Rising to the challenge

Rising to the challenge Rand report echoes Cold War mind-set, overstates threats

Rand report echoes Cold War mind-set, overstates threats Inland nuke plants crucial to energy future

Inland nuke plants crucial to energy future Communist confrontation

Communist confrontationDay|Week