|

BEIJING, May 21 -- An ambitious plan to reform China's manufacturing sector seeks to change the reputation for "Made-in-China" goods.

Since the country began its economic reform and opening-up in the late 1970s, it has gradually risen as one of the globe's largest manufacturers.

Often dubbed the factory of the world, China earned the title at the expense of the environment, with many manufacturers describing their production processes as dull, dirty and dangerous.

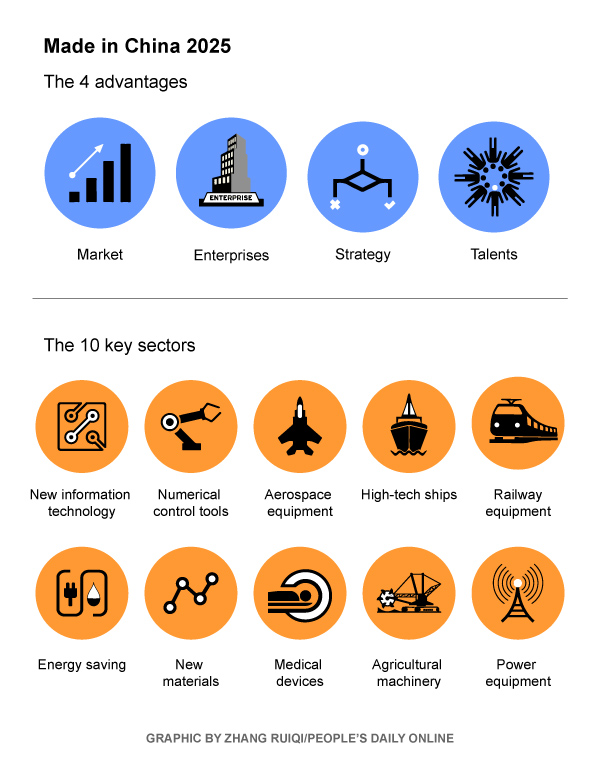

The "Made in China 2025" Plan released on Tuesday aims to reduce the environmental impact of manufacturing and promises to transform the sector, long plagued by overcapacity, into an efficient and sophisticated industry.

It also lays out strategies for the country to upgrade from low-end manufacturing to more value-added and tech-intensive production, and encourages domestic manufacturers to achieve technological breakthroughs across a number of emerging industries from numerical control tools and robotics to aerospace equipment and new energy vehicles.

CHINA'S INDUSTRY 4.0

Many likened the vision depicted in the plan to Germany's Industry 4.0, which emphasizes greater integration with physical production and the virtual world of data.

"Industry 4.0 is about embracing smart manufacturing," said Qu Daokui, president of Siasun Robot & Automation, based in the country's traditional industrial base in the northeast, "whereas the first three industrial revolutions have extended human strength in manufacturing. Industry 4.0 is about making the manufacturing process smart."

Manufacturing upgrades are not only one country's problem, Qu said, but rather a global challenge. Technologies like big data, the Internet, sensors and robots have enabled more efficient manufacturing. Besides, a worldwide manufacturing glut is also forcing the sector to change.

While overcapacity has brought a lot of pain for manufacturers, it also tilts the power balance toward the demand side. Customers worldwide are demanding greater individuality from mass production.

China's worsening labor shortage and rising labor cost also underscores the urgency for the country's manufacturing to upgrade.

"It's wrong to think the problem we have in manufacturing is cyclical or that it stems from a financial crisis. The truth is technological progress is the driving force of the ongoing readjustment in our manufacturing," Qu said.

REDEFINING MADE IN CHINA

Tian Suning, chairman of China Broadband Capital, believes that the new manufacturing that emerges from the latest industrial revolution will be powered by cloud computing and big data. Manufacturing will become more responsive to demands and the economy better structured.

Red Collar, a garment producer based in the eastern Chinese city Qingdao, has invested 1 billion yuan (163.6 million U.S. dollars) over the past 12 years in cloud computing to build an online platform that allows the company to accommodate increasingly individualized demands from its global clients.

The platform enables Red Collar to better understand the unique demands from each client and tailor its manufacturing accordingly. It now makes 3,000 tailored garments daily for its clients in New York and plans to double such highly customized production in the future.

The platform demonstrates how one of the oldest professions can be transformed by cloud computing and big data.

In southwest China's economic powerhouse Chengdu, a plant has showcased what the next level of China manufacturing may look like. Opened in September 2013, the Siemens Electronic Works Chengdu (SEWC) is modelled after its predecessor, Siemens' Amberg Electronics Plant, in Bavaria, Germany.

Both plants produce the company's programmable logic controls, with an extremely low ratio of defects. They also employ very few people and instead use networked machines that automate much of the manufacturing processes.

Production at the Chengdu plant is twice as fast as in Siemens' other plants in China and is expected to overtake its Amberg counterpart soon, which currently produces 1 million parts each year, or one part per second.

GLOBAL WISDOM

A lot of the emerging industries China seeks to nurture in the "Made in China 2025" plan requires cutting-edge technologies, many of which are pioneered by companies from advanced economies like the United States, Germany, and Japan.

To reduce the heavy reliance on foreign technologies, China is gradually ramping up investment in research and development, whose share of GDP has risen from 1.5 percent in 2008 to more than 2 percent last year but still lags behind the 3 percent for developed economies.

The government's growing support for research could mean more opportunities for foreign tech companies who intend to boost their R&D presence in China, says tech consultancy Gartner.

Many research areas with official endorsement, such as cloud computing, smart machines and the integration between Internet and industry, are vital in China's transition toward more sophisticated manufacturing.

Much of this research could eventually translate into substantial market demand. Take cloud computing as an example, Gartner estimates that China's total public cloud market will reach nearly 20.7 billion U.S. dollars, almost four times as much as the level in 2013. A survey conducted by the consultancy last year also shows tech chiefs at large companies treat cloud as the first technology priority to adopt in China.

"If global companies can align their R&D vision and effort with the Chinese government's research priorities, they will achieve a lot of long-term benefits here," said Eileen He, a research analyst with Gartner.

J-11 fighters in air exercise

J-11 fighters in air exercise Beauties dancing on the rings

Beauties dancing on the rings Attendants-to-be join Mr. & Miss Campus Contest

Attendants-to-be join Mr. & Miss Campus Contest Beijing's toughest anti-smoking law takes effect

Beijing's toughest anti-smoking law takes effect Family lives in cave for about 50 years in SW China

Family lives in cave for about 50 years in SW China PLA soldiers operating vehicle-mounted guns in drill

PLA soldiers operating vehicle-mounted guns in drill Blind carpenter in E China's Jiangxi

Blind carpenter in E China's Jiangxi China hosts overseas disaster relief exercise for the first time

China hosts overseas disaster relief exercise for the first time 20 pairs of twins who will become flight attendants in Sichuan

20 pairs of twins who will become flight attendants in Sichuan Obama is sowing discontent in S.China Sea

Obama is sowing discontent in S.China Sea Rescuers work through night to reach cruise ship survivors

Rescuers work through night to reach cruise ship survivors Driving through limbo

Driving through limbo Facing down MERS

Facing down MERSDay|Week